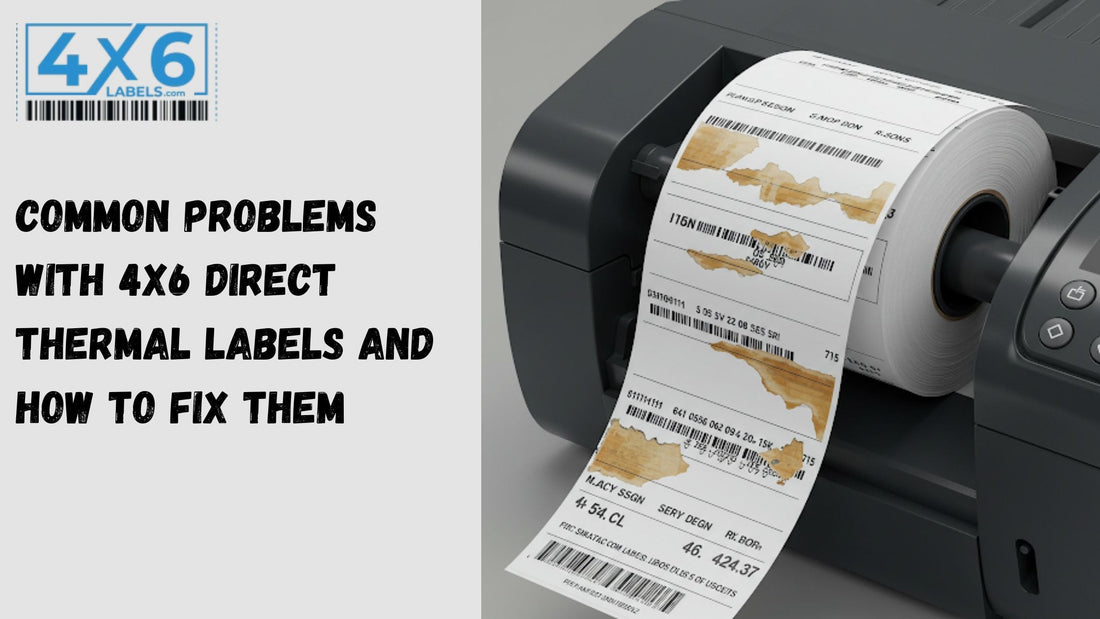

4x6 direct thermal labels are essential for businesses that rely on shipping, inventory management, and retail operations. While these labels provide a cost-effective and efficient way to print, they can sometimes encounter printing issues. Whether you're dealing with faded prints, label jams, or scanning errors, this guide will help you troubleshoot and resolve the most common problems with 4x6 direct thermal labels.

1. Faded or Light Prints

Causes:

-

Low printer heat settings

-

Worn-out thermal printhead

-

Poor-quality labels

-

Dust or residue on the printhead

Solutions:

-

Increase the darkness or heat setting on your printer.

-

Clean the thermal printhead with an alcohol wipe to remove dirt buildup.

-

Replace the thermal printhead if it's worn out.

-

Use high-quality labels designed for direct thermal printing.

Related Blog: 4x6 Direct Thermal Labels: The Ultimate Guide for Efficient Printing

2. Labels Turning Black Prematurely

Causes:

-

Exposure to heat, sunlight, or UV light

-

Poor storage conditions (high temperature or humidity)

-

Contaminants like chemicals or oils on the labels

Solutions:

-

Store labels in a cool, dry place away from direct sunlight.

-

Keep them in their original packaging until needed.

-

Avoid handling labels with oily or dirty hands.

3. Printer Not Recognizing Labels

Causes:

-

Incorrect label size settings in the printer

-

Sensor not detecting labels properly

-

Labels improperly loaded into the printer

Solutions:

-

Check that the printer is set to 4x6 label size in the settings.

-

Clean the label sensor to remove dust or debris.

-

Reload the labels correctly, ensuring they feed smoothly through the printer.

Related Blog: The Best Printers for 4x6 Direct Thermal Labels: A Comprehensive Guide

4. Labels Jamming in the Printer

Causes:

-

Labels not aligned properly

-

Printer rollers are dirty or sticky

-

Damaged label roll

Solutions:

-

Ensure labels are loaded straight and properly aligned.

-

Clean the printer rollers with a lint-free cloth and alcohol.

-

Use a new roll of labels if the current one is damaged or defective.

5. Barcode Labels Not Scanning Properly

Causes:

-

Low print resolution or darkness setting

-

Wrinkled or damaged labels

-

Poor contrast between barcode and background

Solutions:

-

Increase the darkness setting for clearer barcode prints.

-

Ensure labels are smooth and free of wrinkles before printing.

-

Use higher-resolution labels (300 DPI for detailed barcodes).

6. Printer Printing Blank Labels

Causes:

-

Incorrect thermal labels (not direct thermal)

-

Printhead needs cleaning or replacement

-

Printer settings are incorrect

Solutions:

-

Ensure you are using direct thermal labels, not thermal transfer labels.

-

Clean the thermal printhead with alcohol wipes.

-

Check printer settings to ensure darkness and print speed are optimized.

7. Labels Peeling Off or Not Sticking Properly

Causes:

-

Weak adhesive on labels

-

Moisture or dust on the surface

-

Applying labels to rough or textured surfaces

Solutions:

-

Use high-quality labels with strong adhesive backing.

-

Ensure surfaces are dry and clean before applying labels.

-

Press labels firmly to ensure proper adhesion.

Related Blog: How to Store and Handle 4x6 Direct Thermal Labels for Long-Lasting Performance

Conclusion

By identifying the root causes of common issues with 4x6 direct thermal labels, you can maintain a smooth printing process and avoid unnecessary downtime. Regular maintenance, proper storage, and using high-quality labels from 4x6 Labels will ensure optimal performance and longevity.

If you're still experiencing issues after troubleshooting, consider reaching out to your printer manufacturer for additional support. Keeping your printer and labels in top condition will improve efficiency and accuracy in your business operations!